Skip to Content

Free Shipping over X amount

GRS QC HSS Stone Setter's Graver Assortment

Item #

253-252

$188.57

each

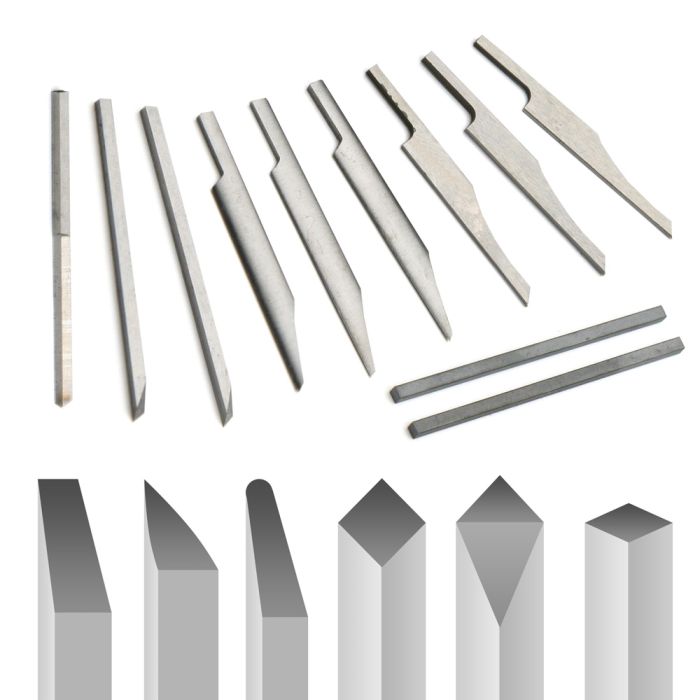

This set of popular gravers for stone setting tasks includes five high speed steel (HSS) quick change (QC) shaped gravers, three GRS GlenSteel gravers, and two carbide graver blanks.

- 2 HSS QC Flat Gravers No. 40 & 42

- 2 HSS QC Onglette Gravers No. 2/0 & 1

- 1 HSS QC Round Graver No. 52

- 2 GlenSteel Square Gravers

- 1 GlenSteel 120° Point Graver

- 2 Carbide Graver Blanks