Skip to Content

Free Shipping over X amount

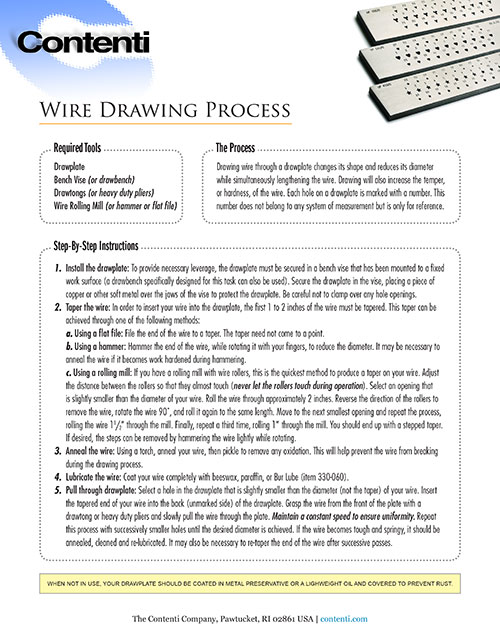

Wire Drawing Process

Drawing metal wire through a drawplate offers you the flexibility of a variety of diameters of wire without having to carry a large stock. The process is clearly explained in detail. Download a pdf of Wire Drawing Process. You can also read a text description of this information below.

Required Tools

- Drawplate

- Bench Vise (or drawbench)

- Drawtongs (or heavy duty pliers)

- Wire Rolling Mill (or hammer or flat file)

The Process

Drawing wire through a drawplate changes its shape and reduces its diameter while simultaneously lengthening the wire. Drawing will also increase the temper, or hardness, of the wire. Each hole on a drawplate is marked with a number. This number does not belong to any system of measurement but is only for reference.

Step-By-Step Instructions

- Install the drawplate: To provide necessary leverage, the drawplate must be secured in a bench vise that has been mounted to a fixed work surface (a drawbench specifically designed for this task can also be used). Secure the drawplate in the vise, placing a piece of copper or other soft metal over the jaws of the vise to protect the drawplate. Be careful not to clamp over any hole openings.

- Taper the wire: In order to insert your wire into the drawplate, the first 1 to 2 inches of the wire must be tapered. This taper can be achieved through one of the following methods:

- Using a flat file: File the end of the wire to a taper. The taper need not come to a point.

- Using a hammer: Hammer the end of the wire, while rotating it with your fingers, to reduce the diameter. It may be necessary to anneal the wire if it becomes work hardened during hammering.

- Using a rolling mill: If you have a rolling mill with wire rollers, this is the quickest method to produce a taper on your wire. Adjust the distance between the rollers so that they almost touch (never let the rollers touch during operation). Select an opening that is slightly smaller than the diameter of your wire. Roll the wire through approximately 2 inches. Reverse the direction of the rollers to remove the wire, rotate the wire 90˚, and roll it again to the same length. Move to the next smallest opening and repeat the process, rolling the wire 11/2” through the mill. Finally, repeat a third time, rolling 1” through the mill. You should end up with a stepped taper. If desired, the steps can be removed by hammering the wire lightly while rotating.

- Anneal the wire: Using a torch, anneal your wire, then pickle to remove any oxidation. This will help prevent the wire from breaking during the drawing process.

- Lubricate the wire: Coat your wire completely with beeswax, paraffin, or Bur Lube (item 330-060).

- Pull through drawplate: Select a hole in the drawplate that is slightly smaller than the diameter (not the taper) of your wire. Insert the tapered end of your wire into the back (unmarked side) of the drawplate. Grasp the wire from the front of the plate with a drawtong or heavy duty pliers and slowly pull the wire through the plate. Maintain a constant speed to ensure uniformity. Repeat this process with successively smaller holes until the desired diameter is achieved. If the wire becomes tough and springy, it should be annealed, cleaned and re-lubricated. It may also be necessary to re-taper the end of the wire after successive passes.

When not in use, your drawplate should be coated in metal preservative or a lighweight oil and covered to prevent rust.