Free Shipping over X amount

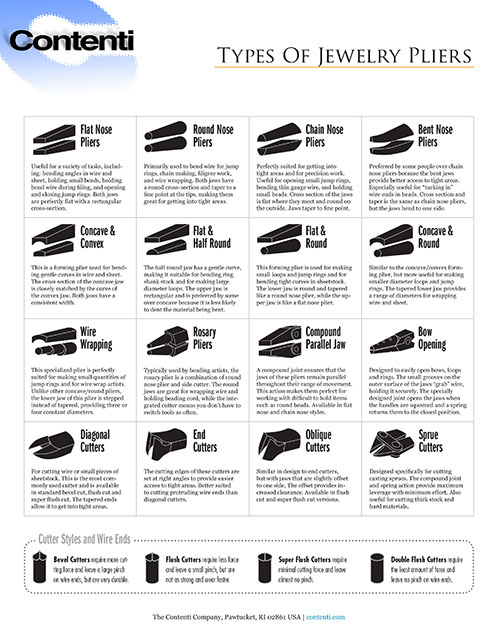

Types of Jewelry Pliers

There are many types of pliers used in jewelry making. Choosing the right pair of pliers is essential to producing high quality work and can make your time in the studio more enjoyable. Download a pdf of Types of Jewelry Pliers. You can also read a text description of this information below.

Flat Nose Pliers

Useful for a variety of tasks, including: bending angles in wire and sheet, holding small beads, holding bezel wire during filing, and opening and closing jump rings. Both jaws are perfectly flat with a rectangular cross-section.

Round Nose Pliers

Primarily used to bend wire for jump rings, chain making, filigree work, and wire wrapping. Both jaws have a round cross-section and taper to a fine point at the tips, making them great for getting into tight areas.

Chain Nose Pliers

Perfectly suited for getting into tight areas and for precision work. Useful for opening small jump rings, bending thin gauge wire, and holding small beads. Cross section of the jaws is flat where they meet and round on the outside. Jaws taper to fine point.

Bent Nose Pliers

Preferred by some people over chain nose pliers because the bent jaws provide better access to tight areas. Especially useful for “tucking in” wire ends in beads. Cross section and taper is the same as chain nose pliers, but the jaws bend to one side.

Concave & Convex Pliers

This is a forming plier used for bending gentle curves in wire and sheet. The cross section of the concave jaw is closely matched by the curve of the convex jaw. Both jaws have a consistent width.

Flat & Half Round Pliers

The half round jaw has a gentle curve, making it suitable for bending ring shank stock and for making large diameter loops. The upper jaw is rectangular and is preferred by some over concave because it is less likely to dent the material being bent.

Flat & Round Pliers

This forming plier is used for making small loops and jump rings and for bending tight curves in sheetstock. The lower jaw is round and tapered like a round nose plier, while the upper jaw is like a flat nose plier.

Concave & Round Pliers

Similar to the concave/convex forming plier, but more useful for making smaller diameter loops and jump rings. The tapered lower jaw provides a range of diameters for wrapping wire and sheet.

Wire Wrapping Pliers

This specialized plier is perfectly suited for making small quantities of jump rings and for wire wrap artists. Unlike other concave/round pliers, the lower jaw of this plier is stepped instead of tapered, providing three or four constant diameters.

Rosary Pliers

Typically used by beading artists, the rosary plier is a combination of round nose plier and side cutter. The round jaws are great for wrapping wire and holding beading cord, while the integrated cutter means you don’t have to switch tools as often.

Compound Parallel Jaw Pliers

A compound joint ensures that the jaws of these pliers remain parallel throughout their range of movement. This action makes them perfect for working with difficult to hold items such as round beads. Available in flat nose and chain nose styles.

Bow Opening Pliers

Designed to easily open bows, loops and rings. The small grooves on the outer surface of the jaws “grab” wire, holding it securely. The specially designed joint opens the jaws when the handles are squeezed and a spring returns them to the closed position.

Diagonal Cutters

For cutting wire or small pieces of sheetstock. This is the most commonly used cutter and is available in standard bevel cut, flush cut and super flush cut. The tapered ends allow it to get into tight areas.

End Cutters

The cutting edges of these cutters are set at right angles to provide easier access to tight areas. Better suited to cutting protruding wire ends than diagonal cutters.

Oblique Cutters

Similar in design to end cutters, but with jaws that are slightly offset to one side. The offset provides increased clearance. Available in flush cut and super flush cut versions.

Sprue Cutters

Designed specifically for cutting casting sprues. The compound joint and spring action provide maximum leverage with minimum effort. Also useful for cutting thick stock and hard materials.

Cutter Styles and Wire Ends

- Bevel Cutters require more cutting force and leave a large pinch on wire ends, but are very durable.

- Flush Cutters require less force and leave a small pinch, but are not as strong and wear faster.

- Super Flush Cutters require minimal cutting force and leave almost no pinch.

- Double Flush Cutters require the least amount of force and leave no pinch on wire ends.