Free Shipping over X amount

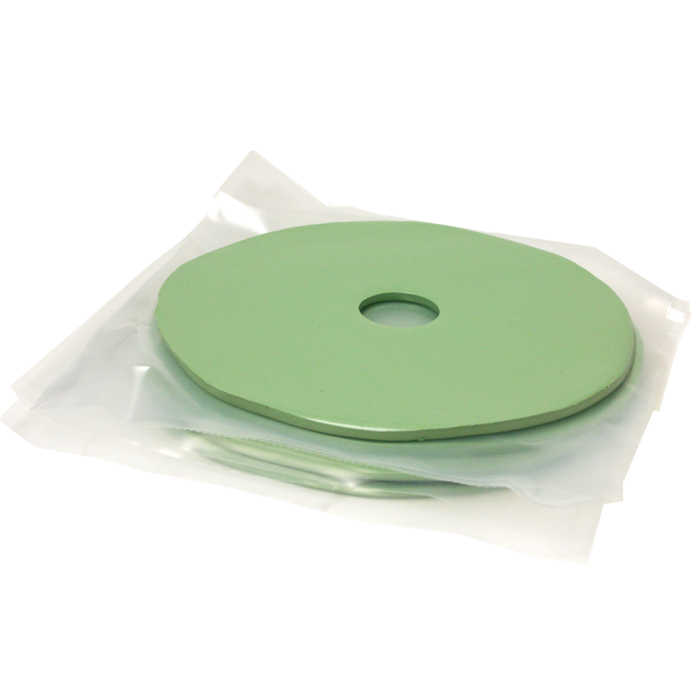

Nicem® Green High Tear Silicone Mold Rubber

Nicem® Green High Tear Silicone is formulated for use with tin and lead alloys when there is a need for additional tear strength. It replaces the now-discontinued Marathon and Millennial Silicone Rubbers. Because of its lower cost versus the Nicem Blue and Yellow silicones, it is also commonly used for shorter runs in zinc alloys. Like all Nicem silicone, Nicem® Green High Tear Silicone is formulated and blended using only the highest quality polymers and fillers.

Every silicone rubber mold set has a nominal thickness of 1" and consists of four 1⁄4" thick sections. The term "durometer" used in the table below refers to the relative hardness of a rubber compound when cured. The higher the durometer, the harder the rubber compound is.

Product Details

| Rubber Series | Applications | Durometer | Flexibility | Tear Resistance | Temperature Resistance |

|---|---|---|---|---|---|

| Nicem White | A backing material for more expensive mold compounds. | 64-66 | Medium | Medium | Medium |

| 200 Series Red | Polyester and polyurethane resins, lead and tin alloys, and as a backing material for more expensive mold compounds. | 63 | Medium | Medium | Medium |

| 500 Series White | Fishing lures, high lead content alloys and polyester and polyurethane resins. | 57 | Med-High | Medium | High |

| Nicem Green High Tear | Tin and lead alloy pieces with substantial undercuts. Often used for short runs in zinc alloys. | 55-57 | High | Very High | High |

| Nicem Black Ultra High Tear | Tin and lead alloy pieces with very substantial undercuts. | 57 | High | Highest | High |

| Nicem Yellow | Zinc, tin and lead alloys, polyester and polyurethane resins. | 59-62 | High | Med-High | Very High |

| Nicem Blue | Zinc, tin and lead alloys. Polyester and polyurethane. | 63-65 | Medium | Medium | Highest |

| Nicem Green Low Temperature Cure | Used when very low shrinkage is necessary or desirable. | 49-51 | Very High | Very High | Med-High |